PureView PrecisionTM Ultrasound Transducers

Utilizing optical and semiconductor fabrication techniques, Imaginant manufactures the PureView PrecisionTM line of RoHS-compliant delay-line ultrasound transducers with center frequencies ranging from 50 MHz to 250 MHz (higher and lower transducer frequencies are also available). Imaginant's precision-manufacturing process produces transducers that exhibit high reliability and high uniformity from device to device. This manufacturing consistency enables uniform test system performance to be attained across multiple systems. Imaginant transducers are available in focused and flat-face models that can be produced with minimal-damping for applications requiring maximal sensitivity or with maximal-damping and high-bandwidth for applications requiring the highest-degree of temporal precision.

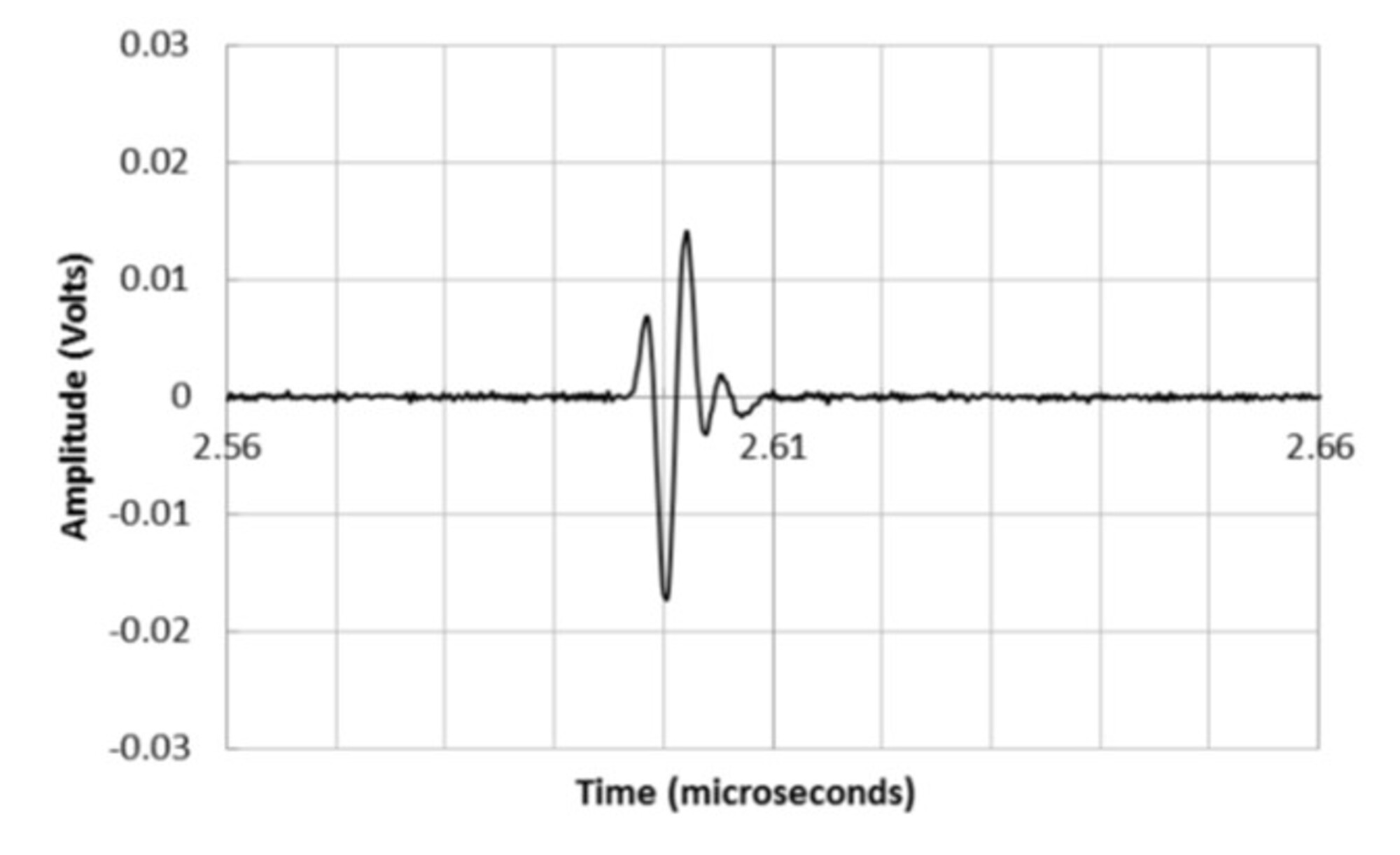

A typical delay-line echo from an Imaginant high-frequency transducer is shown below left. This well-damped transducer exhibits a 270 MHz peak frequency and broad bandwidth as indicated in the echo's frequency spectrum shown below right.

Please contact us for details on our high-frequency contact and immersion transducer models, customization options, and lead times. We are happy to consult on a transducer design with the precision that will enable your success.

As their name implies, contact transducers are placed into direct contact with test objects with a thin layer of couplant between the transducer and object. The couplant facilitates the transfer of ultrasound from the transducer into the object, but in addition the central region of the transducer's face must make good contact with the surface of the test object. Imaginant's standard contact transducers are flat faced, but customization to other shapes is possible. To optimize the transducer for a specific measurement, the transducer's center frequency, beam diameter, degree of damping, and delay line length must be all be optimized. We welcome the chance to consult with you on your transducer requirements.

Immersion transducers employ a coupling medium such as water to convey ultrasound from the transducer to a test object. These transducers are commonly used in equipment such as scanning acoustic microscopes and often incorporate a lens on the transducer's face to focus the ultrasound beam so as to improve the detection of small features in the test object. The transducer's performance must be optimized for a given application which includes careful selection of the transducer center frequency, beam diameter, degree of damping, lens design, and delay line length. Feel free to contact us to discuss your system and transducer requirements.